Do you run a construction company? here are 20 tips for efficiently handling and storing materials on construction sites to minimize damage or theft.

Storage and handling of materials in the construction industry is not easy. Due to the large number of resistant and temperature sensitive materials, the contractor may face very serious material safety issues. From lumber and brick to chemicals and glass, different materials require different methods of storage and handling in order to maintain their usefulness.

For this reason, we will offer you various tips to help you properly store and handle various materials on your job site so as not to lose them and compromise their usefulness.

20 smart tips for efficient material handling and storage on the job site

- Be careful with pallets

The use of pallets for loading and transporting materials is widespread in the construction industry. You need to make sure that the pallets you use are in good condition. Cross-stacking and other secure loading methods are necessary to keep your pallets safe.

Bundle and secure unstable loads and repack them if necessary. There is no need to endanger the equipment and the lives of those who use it. Make sure you know the exact type and size of pallets required for the load you expect to receive. They should be suitable for the type of equipment you are using to unload materials.

- Use dedicated material racks

Taken together, these two guidelines justify the use of multiple racks of highly specialized materials specifically for the materials in your warehouse. You won’t store the bags in flat glass storage, and your glass won’t serve as a simple floor stand for long. The solution is to examine your materials and select racks designed to support each type of product stored in your facility.

- Know your weight limits

Each material has its own weight limit and you have to find it. Failure to do so can lead to many preventable disasters. Never exceed the stated weight limit of a storage unit, regardless of the temptation.

In general, this means that you should choose storage racks made of sturdy steel, with weight limits that far exceed the expected storage loads. For example, BHS floor and sheet metal braces have a lift capacity of 8,000 lbs.

- Choose your storage area carefully

Materials can suffer from improper handling and storage. For example, untreated wood can get wet and make it unsuitable for framing. Make sure materials are weatherproof, stored properly – not on bare or uneven surfaces – and handled appropriately. Wood must be at a certain moisture level before it can be used for flooring and framing.

Get clear title (such as receipts) for offsite materials and get insurance coverage in the event of theft or liquidation from your builder. Cameras can play an important role: documenting problems immediately, discussing them immediately with the manufacturer, and taking pictures if there are additional problems.

Storage locations should be chosen at the start of a project design and you should make sure that they are clearly defined at the start of the project. This will prevent areas from overflowing and ensure they are suitable for materials such as a drywall area. You should also ensure good site security, such as perimeter fencing and security personnel, to minimize the risk of material loss through theft or vandalism.

- Do not stack drums, drums or barrels directly on top of each other

This is not, no, regarding the safe storage of building materials. Instead, always use a pallet or wooden planks between coats. This creates a stable flat surface for the top layers.

- Store similar items together

To get the most out of your materials, you need to keep similar items together. You should also have a dedicated team that can offload and distribute documents to the point of use, as this will help avoid duplicate processing and reduce the cost of hiring specialists.

Once the materials are delivered to the site, contractors must confirm that they have received the materials, either manually or using an electronic system such as tagging.

- When stacking wood stacks should be relatively short and be sure to remove any embedded nails

OSHA recommends closing wood piles to a height of 16 feet when workers handle material manually. If you are using mechanical equipment to move material to access lumber, OSHA recommends a maximum stack height of 20 feet.

Nails not only pose a danger to workers handling used wood, but they make it impossible to safely install this common building material. It may take a while, but it is worth removing all nails from the wood before putting them away.

- Block stacks of cylindrical materials such as bars and lengths of piping at each end to prevent collapse

Poles, steel rods, and piping pose unique storage challenges; if placed in the wrong posts, they can easily tip over, causing a dangerous avalanche of heavy materials. This is why OSHA recommends blocking cylinder stacks at each end to hold them securely in place. BHS ground posts include removable retainers for maximum combination of safety and access for all types of materials

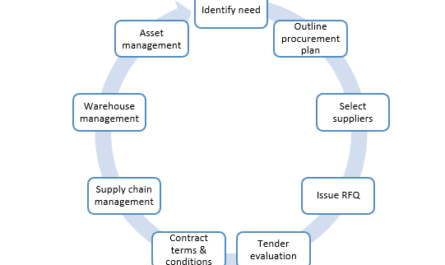

- Use the right storage solutions

Your storage arrangements should always be tactfully designed to accommodate the physical constraints and inventory schedules (what comes in and when, what will be used, when, etc.) specific to your job site.

Remember the following:

- Consider the weather. Some consumables can be stored outdoors (placed on pallets to protect them from soil moisture and covered with a roof or tarp), while others (like some power tools) need to be stored internally when not in use.

- Sort content as it becomes available, prioritizing items in the order you need to ensure accessibility.

- Make sure you have enough space to sort waste by type (metal, wood, drywall, etc.) before it is removed from the job site.

- Having the right storage solutions will simplify material management throughout the project.

- Check equipment, tools and machinery before starting work

Before starting any work, you should always check construction equipment, tools, and machinery on the job site to make sure they are safe to use. For example, proper planning and staging before the start of the work day will ensure that employees have the right tools and equipment they need to get the job done.

- Site security

If necessary, you must ensure adequate safety on the construction site. This will allow you to store the expensive materials that you have there. Restricted site access is not just about preventing theft or damage to equipment. You must have security measures that restrict access to the workplace after hours to protect workers or anyone else from potential construction hazards. Strict safety rules must always be observed.

- Minimize the distance people have to travel to receive materials

Every minute in your workplace counts, so it’s important to have supplies on hand. Ideally, consumables should be stored as close to the installation site as possible to reduce the time your team has to spend finding and replacing tools and equipment. Consider storing small items in specialized, well-organized containers and restocking them from on-site or off-site inventory as often as needed.

- Provide appropriate training

Training is a key component of workplace safety and the handling of equipment in all industries. Many project managers assume that all workers know about construction site safety procedures on the job site, but this is not the case. Lack of training for workers, whether they work for days or months, is one of the factors contributing to the increase in injuries and fatalities on construction sites. It can also lead to mismanagement of many materials.

- Promote and apply best practices

In all working environments, the promotion and application of best practices and safety procedures on the job site play a major role in ensuring the safety of all. Make sure management, supervisors, and even employees play by rules, follow work protocols, and encourage positive behavior.

You should also encourage your workers to participate in a construction site safety program. They can help by offering ideas to improve their own safety. Encourage workers to communicate safety concerns and risks to leaders and project managers. Management is expected to take immediate action in the event of a reported hazard. Most incidents can be easily avoided if someone is speaking, so remind workers to be open when they see something.

- Follow the rules when stacking drums

If you want to avoid a disaster when stacking your barrels, you have to play by the rules. When stacking barrels and drums, workers should:

- stack drums, barrels and drums symmetrically.

- Hammer down the lower tiers of barrels, barrels, and kegs so they won’t roll if stored on the sides.

- Place boards, sheets of plywood, or pallets between each tier of drums, barrels, and drums to create a solid, flat stacking surface when stacked at the end.

- Eliminate manual tasks as much as possible

Instead of lifting manually, use the equipment in the safest way possible. , Avoid pushing, pulling and transporting with conveyors, forklifts, slides or hand trucks. Using mechanical equipment can be costly for your job, but it can make your job easier and help you save materials and labor.

- Use clear signs

It is important to use clear signage so that all construction site safety procedures are known, including the 24 hour emergency number and clear directions to the site office. A visible sign helps workers remember and understand the safety protocols that must be followed at all times.

- Keep your site in good working order

The law states that you must keep all parts of your job site in “good condition” and each work area clean, and your materials must be properly stored. The goal is to achieve what is commonly referred to as a good level of “housekeeping” throughout the site.

In addition, all contractors must plan, manage and supervise their work so that it can be carried out safely and without risk to health. This includes careful planning of how the site will be kept clean and how safety measures can be taken. Therefore, if you do not want to properly manage your documents, do so in the name of the law.

- Use the right material handling equipment

When thinking about how to handle materials or how to place them correctly in a warehouse, think about the equipment that can help you. Whenever possible, use: trucks, forklifts, carts, carts, wheelbarrows, elevators, etc.

Save your back and improve your work efficiency by using the right tool for the right job. If manual assistance is required at any stage of the job, make sure there are enough workers to divide the job. By improving your handling procedures, your safety record will improve and your work tools will be better.

- Only move when necessary

When processing a project for a construction site, you need to make sure that the materials are only moved. This should reduce the wear and tear that can be caused to your materials by this movement. When planning to move, send or receive material, consider all parts of the operation. You should ask these questions;

- How will it be transported?

- Are the workers sufficiently experienced?

- Do you have enough workers to do the job? right?

- Is the operator of the vehicle sufficiently experienced for the job at hand?

- Is the parcel or cargo size adequate?

How to choose the right one? Answering these questions will help you protect your tools and materials while driving.